How AI Is Used in Predictive Maintenance

Artificial intelligence plays a pivotal role in predictive maintenance by analyzing vast amounts of operational data. It employs machine learning algorithms to identify patterns indicative of potential equipment failures. This methodology not only enhances the reliability of machinery but also optimizes maintenance schedules, thereby reducing costs and unplanned downtime. As industries increasingly adopt these AI-driven strategies, the implications for efficiency and decision-making warrant further exploration into their transformative impact.

Understanding Predictive Maintenance and Its Importance

Predictive maintenance represents a strategic approach to asset management that leverages data analytics to forecast equipment failures before they occur.

By utilizing advanced data analysis techniques, organizations can enhance equipment reliability, minimizing downtime and maintenance costs.

This proactive strategy empowers businesses to optimize operational efficiencies, ensuring that resources are allocated effectively while maintaining the freedom to adapt to evolving technological landscapes and equipment needs.

Role of Artificial Intelligence in Predictive Maintenance

The integration of artificial intelligence (AI) into predictive maintenance frameworks significantly enhances the capability to analyze vast amounts of data generated by industrial equipment.

Through sophisticated data analysis techniques and machine learning algorithms, AI identifies patterns that predict failures, optimizing maintenance schedules.

This proactive approach not only minimizes downtime but also fosters operational efficiency, empowering industries to make informed, data-driven decisions for equipment management.

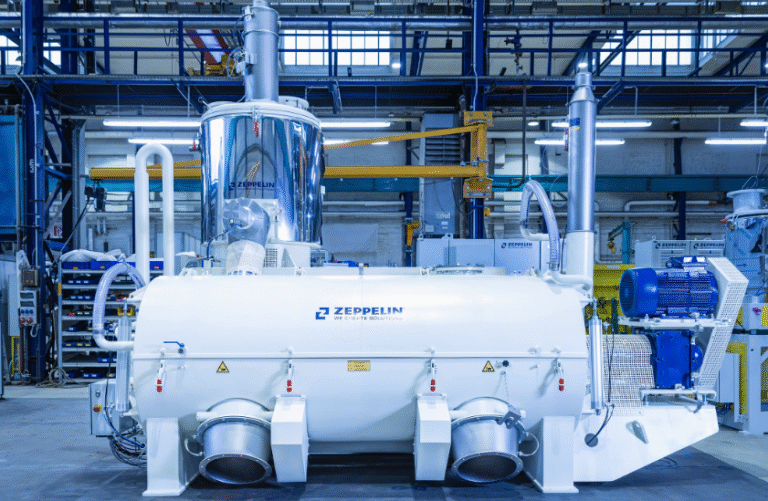

Real-World Applications of AI in Industrial Settings

As industries increasingly adopt AI technologies, numerous real-world applications have emerged that demonstrate the transformative potential of these systems in industrial settings.

Integrating sensor technology with advanced data analytics allows organizations to monitor equipment health in real-time, predict failures, and optimize maintenance schedules.

This proactive approach enhances operational efficiency, reduces downtime, and minimizes costs, showcasing the effectiveness of AI in predictive maintenance strategies.

Future Trends and Innovations in AI-Driven Predictive Maintenance

Although advancements in AI-driven predictive maintenance have already transformed industrial practices, the future promises even more significant innovations and trends.

Enhanced data analytics will enable real-time monitoring and predictive capabilities, while machine learning algorithms will further refine maintenance schedules, minimizing downtime.

Integration with IoT devices will facilitate seamless data collection, driving proactive strategies that empower industries to optimize asset performance and reduce operational costs.

Conclusion

In conclusion, the integration of AI in predictive maintenance serves as a beacon of innovation, illuminating pathways to enhanced operational efficiency. By harnessing data-driven insights, industries can proactively address potential failures, transforming maintenance from a reactive necessity into a strategic advantage. As organizations increasingly adopt these advanced technologies, the evolution of predictive maintenance is poised to redefine asset management, ensuring reliability and cost-effectiveness in an ever-competitive landscape. The future, therefore, holds promising potential for further advancements in this domain.